1. Scientific and technical background for the development of coal-fired ultra-supercritical steam power plants.

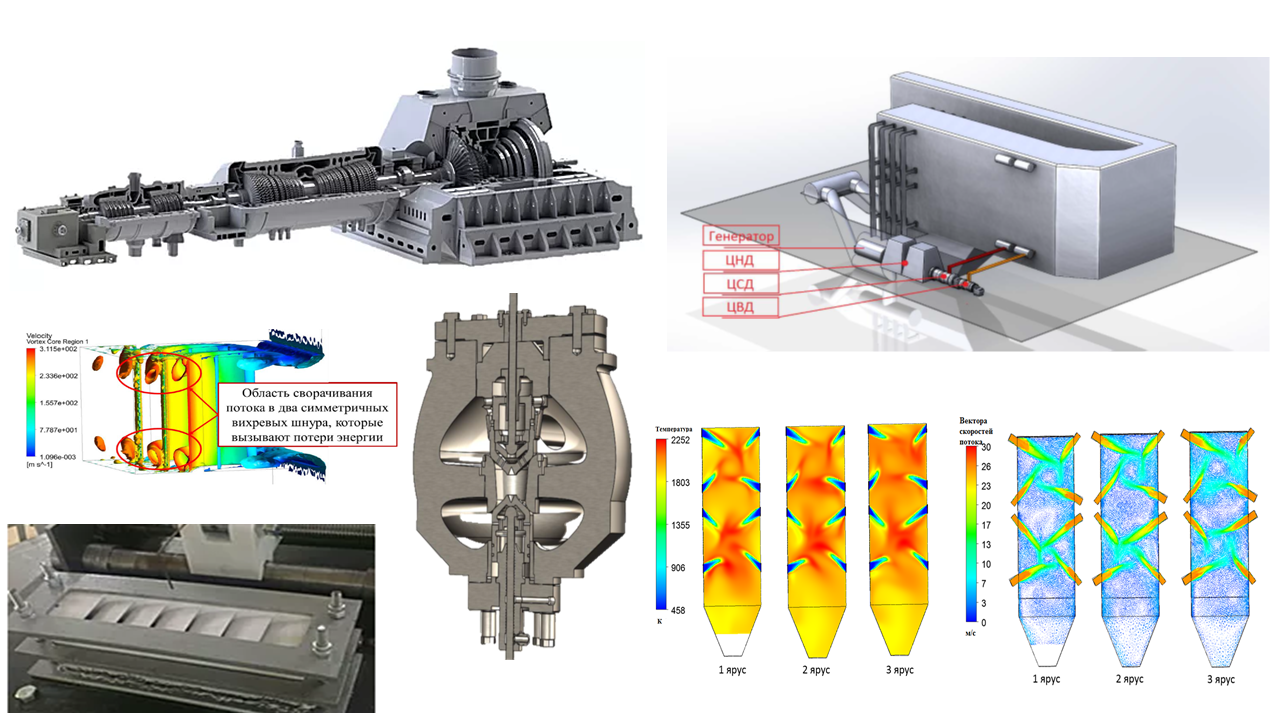

The project aim: the

main components development for the energy boiler and steam turbine unit

ensuring the creation of highly efficient and reliable power plants with

ultra-supercritical steam parameters (pressure over 35 MPa; temperature over

720°C) with a gross efficiency about 50%.

The main results:

1.

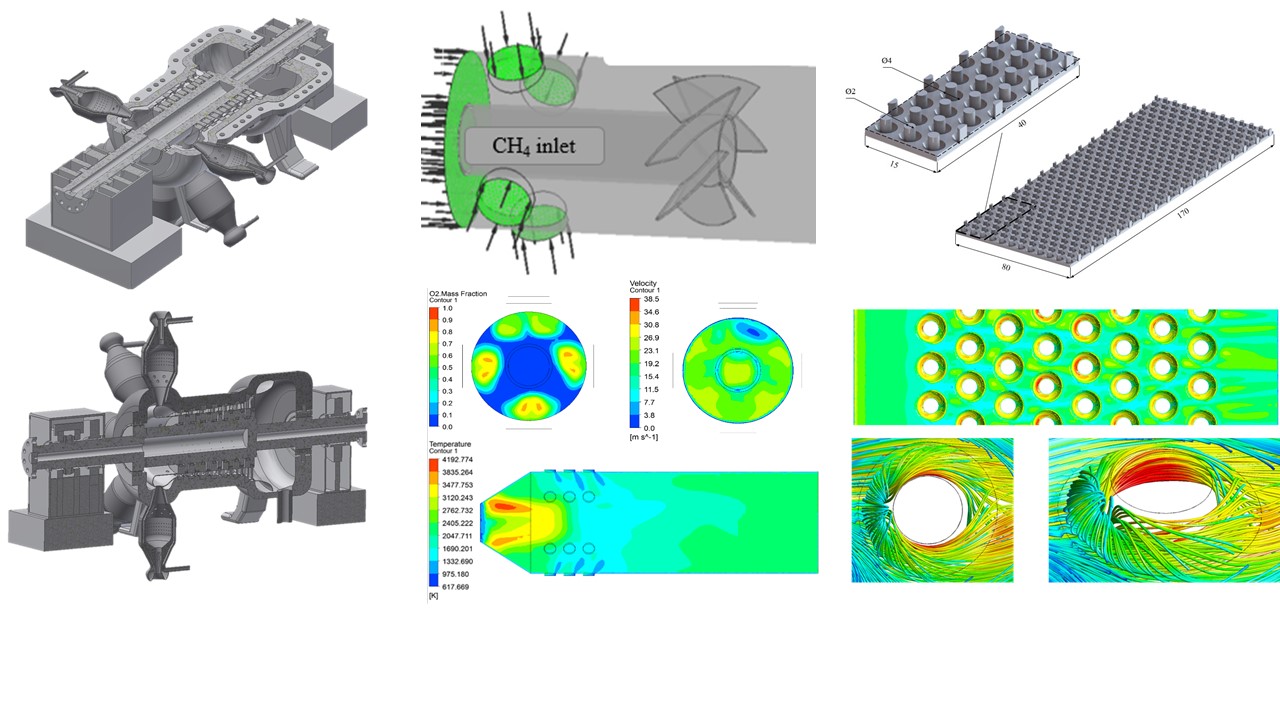

a flow path of the ultra-supercritical steam turbine

has been developed

2.

a new horizontal layout of a pulverized coal-fired

energy boiler has been developed, which reduces the cost of the power plant by

decreasing the high-temperature steam pipes’ length.

2.

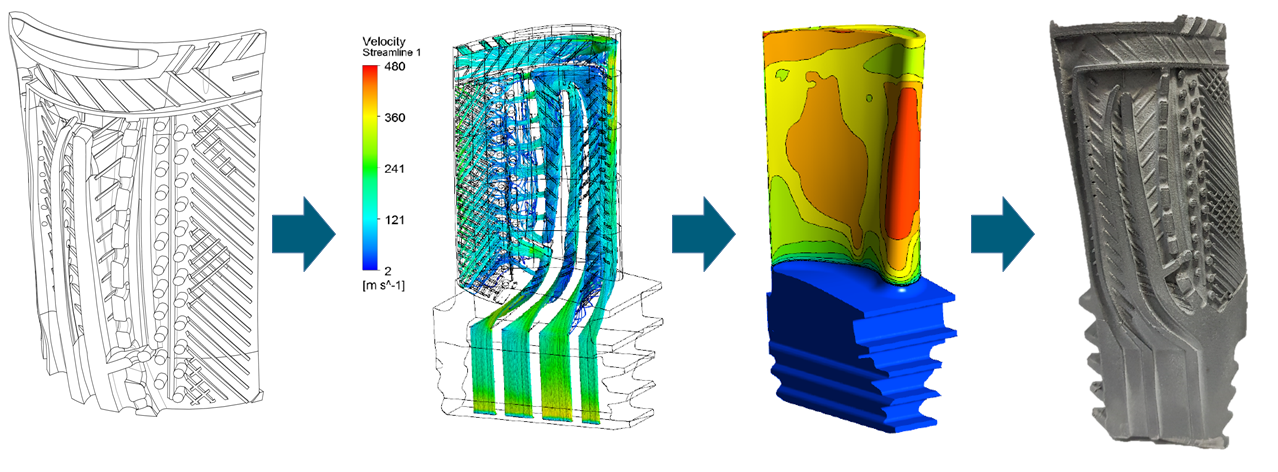

Research and development of the heat transfer augmentation methods for cooling systems of high-temperature gas turbine blades and technologies for advanced verification of

thermohydraulic models.

The project aim: the

development of the design solutions for blade cooling of the Russian gas

turbines with an initial temperature higher than 1300°С to ensure their reliable operation.

The main result: gas turbine

blade cooling system for the initial temperature of 1300°C was designed and

tested.

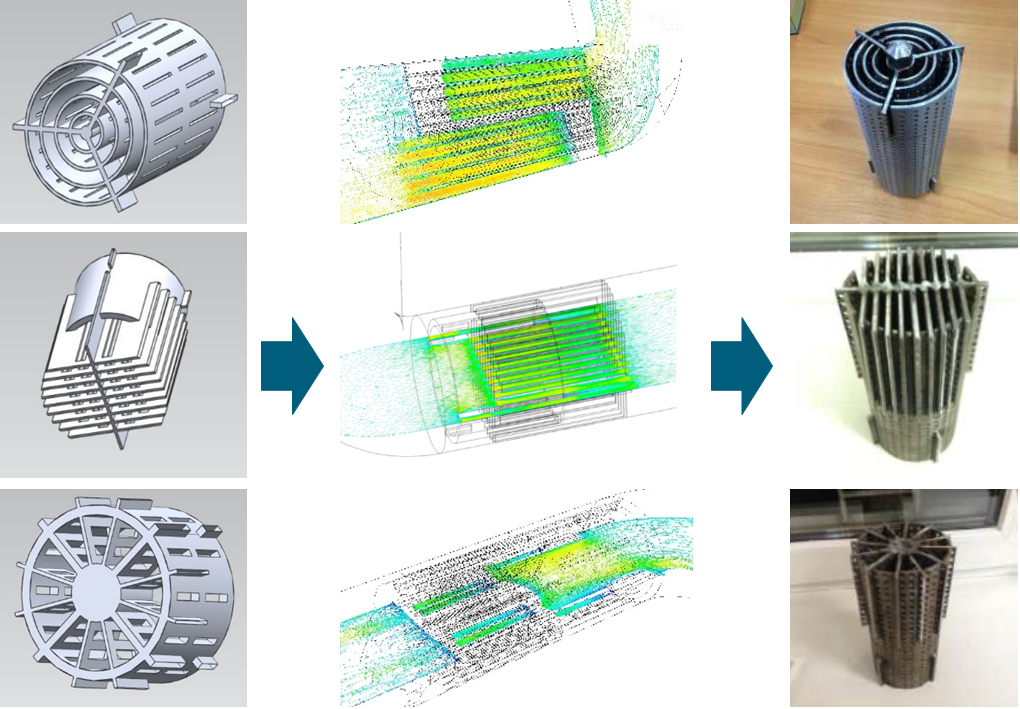

3. Research and development of the pipeline flow stabilizers.

The project aim: the development

of flow stabilization devices reducing the dynamic loads and vibrations in

piping systems for transporting water, air, and steam.

The main result: the all-mode flow

stabilizers were designed (annular, plate, sectional).

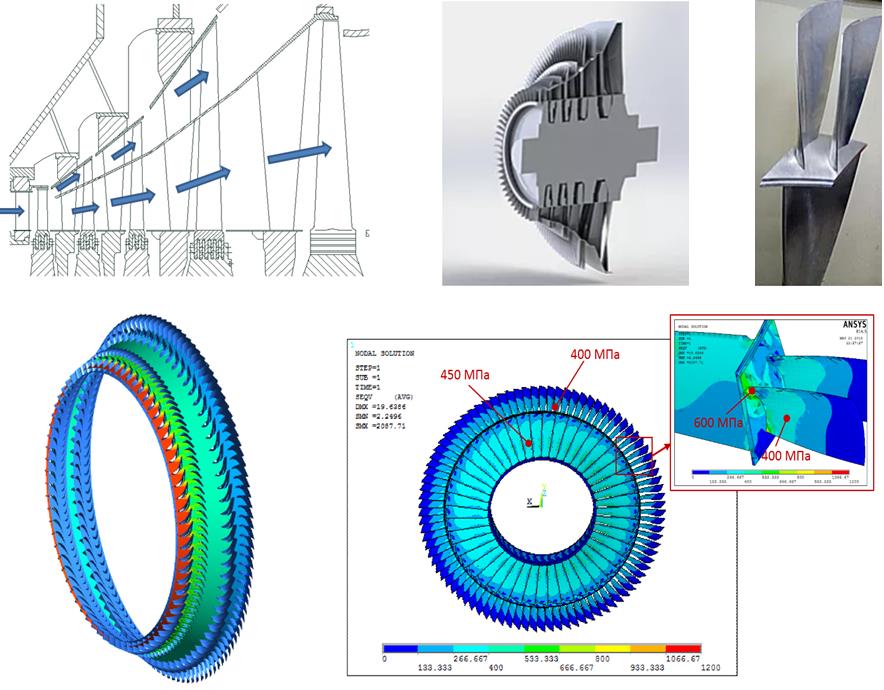

4. Research and development of the new low-pressure turbine with increased capacity for high-power power plants.

The project aim: the

development of low-pressure turbine with increased capacity ensuring reduction of the specific

metal content of powerful steam turbines by 15%.

The main result: the construction

of the low-pressure turbine with increased capacity was designed.

5. Thermodynamic analysis and development of the design fundamentals of high efficient carbon dioxide power cycles.

The project aim: the formation

of a scientific and technical background for the development of Russian

oxy-fuel combustion power cycles and the development of the construction of a high-temperature

supercritical carbon dioxide gas turbine, oxy-fuel combustion chamber, and regenerative

heat exchanger.

The main results:

|

1. The flow path of CO2 turbine was designed. The film cooling system for the high-temperature blades was developed.

|

2. The sketch of the oxy-fuel combustion chamber was developed.

|

3. The heat transfer augmentation methods for CO2 turbines were developed.

|

|

|

6. Research and development of an energy boiler for a bioenergy power unit with increased autonomy.

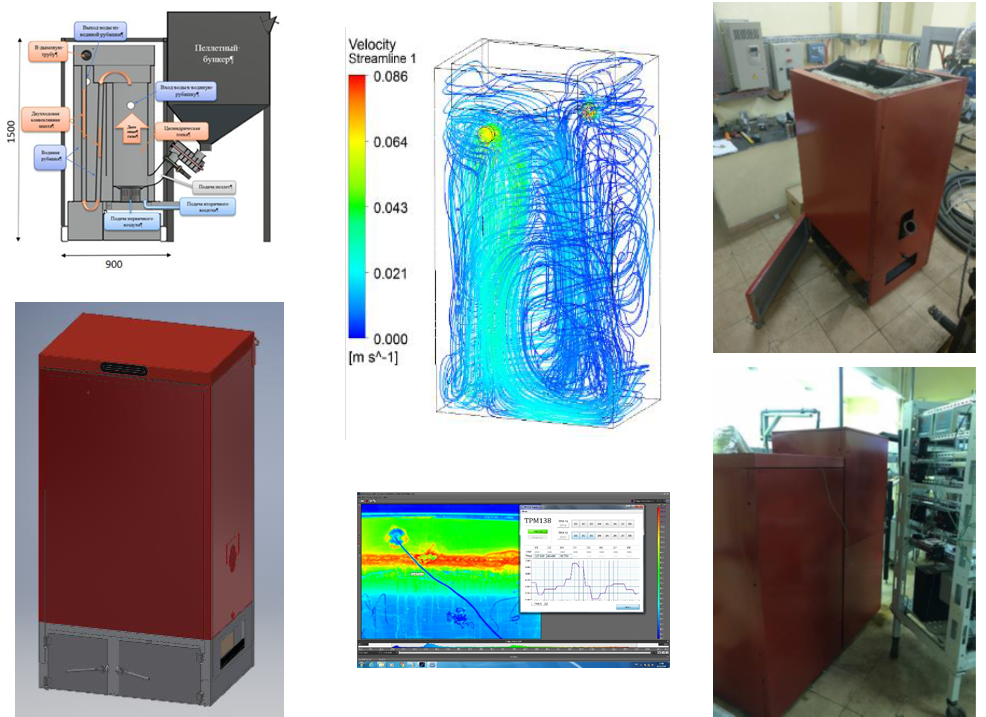

The project aim: development and testing of a prototype pellet boiler with a two-stage combustion chamber providing high efficiency up to 92%.

The main result: a prototype of a pellet boiler was manufactured and tested

|

|

| 3D model of the biofuel-fired boiler

|

The results of CFD and experimental measurements using a thermal imager

|

The manufactured prototype of the biofuel-fired boiler

|